- Slotting Machine Tools

- Slotting Attachment For Milling Machine For Sale

- Indexable Slotting Milling Cutters

- Slotting Machine For Sale

- Cnc Slotting Machine

The milling machine attachments are intended for the purpose of developing the range of operations, versatility, production capacity and accuracy of machining process. The different milling machine attachments are:

Daljit is a manufacturer, exporter, supplier of Vertical Slotting Machine, Geared Slotting Machine, Heavy Duty Slotting Machine, Precision Slotting machine, Milling Machine and auto feed of all sizes in India. Get the best deals on Bridgeport Attachment Metalworking & Milling Machines when you shop the largest online selection at eBay.com. Free shipping on many items. We are Daljit Machines, Manufacturers, Suppliers & Exporters of all kinds of Slotting & Milling machine located in the Industrial Hub of Punjab - Ludhiana, the Manchester of India. Quality Policy We, at Daljit, are committed to supply quality products at competitive prices, for worldwide customer satisfaction as suggested by ISO 9001-2008.

- Vertical milling attachment

- Universal milling attachment

- High speed milling attachment

- Slotting attachment

- Rotary table attachment

- Indexing head attachment

Vertical Milling Attachment

A horizontal milling machine is converted into a vertical milling machine by the vertical milling attachment. Vertical milling attachment is mounted on the face of the column of the horizontal milling machine. The attachment along with the spindle can be swiveled to any angle for machining angular surfaces.

UniversalMillingAttachment

Slotting Machine Tools

By having the universal milling attachment, the spindle of the machine can be swiveled about two perpendicular axes. This arrangement permits the spindle axis to be swiveled at practically any angle to machine any angular surface of the work. This attachment is supported to the over arm to operate it at higher spindle speeds.

HighSpeedMillingAttachment

This attachment is used to increase the regular spindle speeds by four to six times. Milling cutters of smaller diameters are operated efficiently at higher cutting speeds. This attachment is bolted to the face of the column and enables the cutter to be operated at speeds beyond the scope of the machine.

Slotting Attachment For Milling Machine For Sale

SlottingAttachment

The rotary movement of the spindle is converted into reciprocating movement of the ram by a crank arrangement. This attachment makes the milling machine to be converted into a slotting machine by accepting a single point slotting tool. The tool is mounted on the ram and used for cutting internal or external keyways, splines etc., It can also be swiveled to machine angular surfaces.

RotaryTableAttachment

It is a special device bolted on top of the machine table to provide rotary motion to the workpiece in addition to the longitudinal, cross and vertical movements of the table. It consists of a circular table provided with ‘T’ – slots mounted on a graduated base. The driving mechanism of this attachment is made possible by a worm and worm gear.

Indexable Slotting Milling Cutters

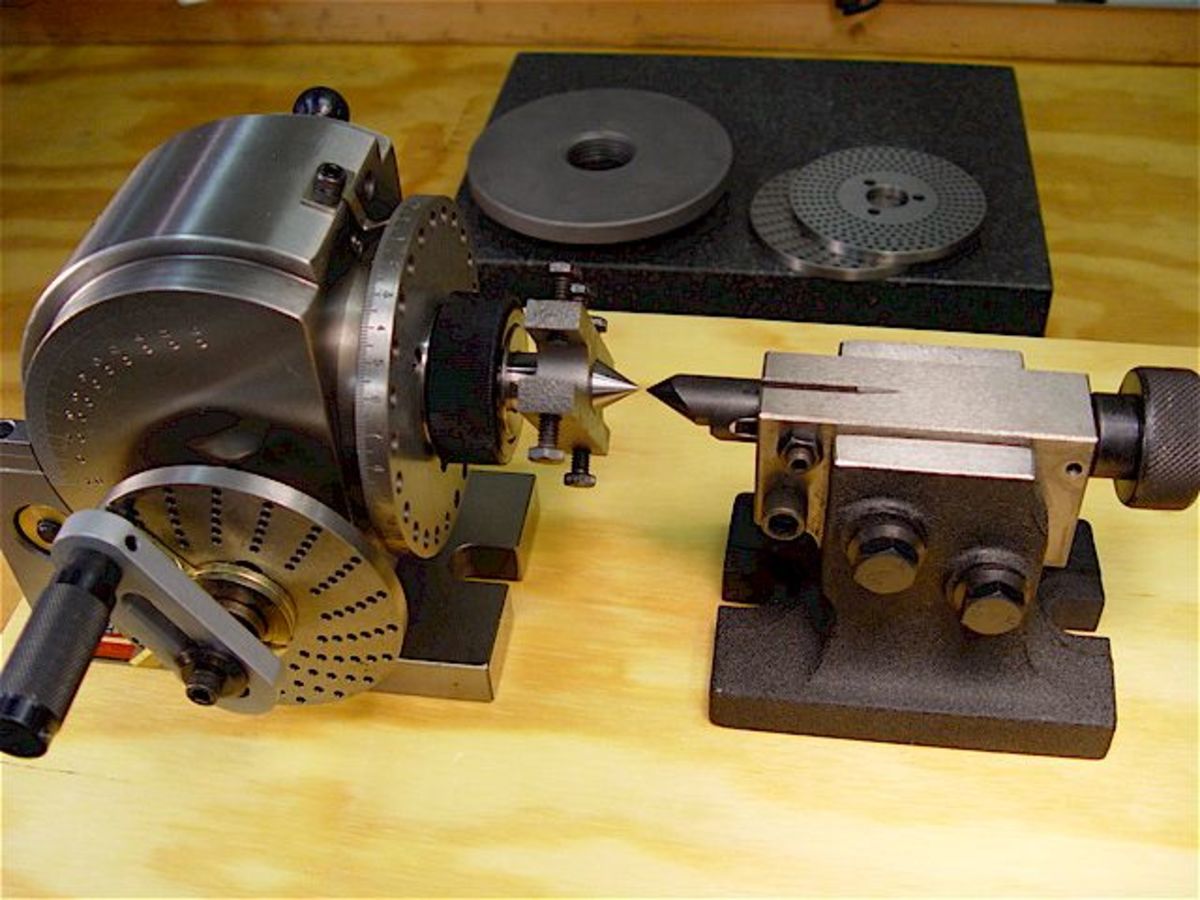

IndexingHeadAttachment

It is a special work holding device used for dividing the periphery of the work into any number of equal divisions. The work is held in a chuck of the dividing head spindle or supported between centers. It is also used in shaping machines and slotting machines. While machining gears, spirals, clutches and ratchets, this dividing head is used to divide the circumference of the work into any number of equal parts.

Slotting Machine For Sale

SYNOPSIS

There are number of machine tools producing round and taper holes. But many engineering components require square and non-circular holes. At present square and other non holes are produced using CNC machines or spark erosion or slotting machines. But there is no quality machine tool to produce square and polygon holes at minimum cost. Thus we made an attempt to design and fabricate an attachment for drilling machine which would produce square and polygon holes much more easily than the current method. This will be very useful to seat bolt heads etc.

This attachment can be though of an inversion of the “Cam and Ball mechanism. This attachment can be fitted either in drilling machine or vertical milling machine. A complete design for this attachment for a size of maximum 20mm square and polygon holes has been successfully done and tested using an upright drilling machine. For different sizes of holes less than 20mm the tool can be changed. Similar designs can be made for any size and any number of sides to avoid lot of setting time and pre-machining procedures involved in current methods and very useful in case of mass production.

INTRODUCTION

Coimbatore is a highly industrial city. This is mainly due to entrepreneurship of local peoples. As there is no public sector undertaking. The small-scale industries though have lathe and other general-purpose machine tools; they find it difficult to get a good finished square and polygon shaping the components. For producing square and polygon holes we have slotting and broaching machines. But it is slow process, the cost is high and setting time is more. A lot of time and manual work is involved in these methods.

So this project “FABRICATION OF SLOTTING ATTACHMENT IN DRILLING MACHINE” is very much useful, if it is provided with good quality form tools of different shapes and sizes. Hence a need exists for attachment which can produce non-circular holes at minimum cost. Thus an attempt is made to design and fabricate such an attachment.

WORKING PRINCIPLE

To obtain a hole of desired shape, first the maximum size of hole that can be inscribed in it is drilled using a conventional drill bit. Now without changing the job and spindle settings, the taper shank of shaft is introduced into the spindle. When spindle rotates the shaft receives the drive and transmits it to the sleeve. The other end of the sleeve is connected to the main shaft which is made up of mild steel 15 mm shaft. The bevel gear and cam mechanism is used to transfer the rotary motion in to the reciprocating motion.

Thus the stub reciprocates three times per revolution of the sleeve. The downward stroke is the cutting stroke. Thus the tool reciprocates with small amplitude and high frequency. The stroke length is equal to distance between the upward and downward movement of the crank shaft. ADVANTAGES

The accuracy of shape.

Comparatively less labour cost than other methods.

Less physical and mental fatigue.

Bolts and nuts can be easily seated.

Machining time is less.

DISADVANTAGES

Not so effective for very hard materials.

Feed should be given intermittently.

Overload should be avoided.

Chips remain in the hole.

When this unit was completed and tested using an Upright Drilling Machine vibrations where experienced due to the radial play of the internal parts. Thus the square could not be machined with that much accuracy. Thus to overcome this defect a thin walled cylindrical hollow sleeve has been introduced between the casing and sleeve. The cylindrical sleeve and the internal parts have very less clearance just to allow them to rotate and no radial play. Thus the vibrations have been arrested. The material used of the sleeve is Mild Steel.

OTHER APPLICATIONS

This drilling machine attachment shall be utilised for other purposes other than machining form holes. This unit eliminates the presence of slotting machine in machine shop. Of course it may not be useful for all the jobs that a slotter can perform. This is because of lack of rigidity that a slotter has. But for small job works like machining a keyway etc can be very well performed by using a suitable tool bit fixed in the tool holder using a bar. Now moreover by giving a very high RPM and minimum feed the frequency of reciprocation can be increased. When this high frequency reciprocation are applied on the job through an abrasive slurry, a hammering effect takes place on the work piece and any complicated shape in the tool can be produced in the job as a female part of the tool. The abrasive slurry consists of mixture of water and abrasive particles. This slurry and work piece is enclosed in a container.